With those words, we were challenged to help think through the wishlist for a new motor onboard a WID (water injection dredger) from our Dutch pride, Van Oord. Read more...

The WID in question had a motor that turned out to be unsuitable for the pump and was looking for a suitable electric motor with specific dimensions, torque, and power. However, this motor was not a standard type.

Together with all parties involved, we defined the desired parameters. It soon became clear that the combination of torque, power, and speed was a challenge. Add limited dimensions to the mix, and it becomes a real puzzle!

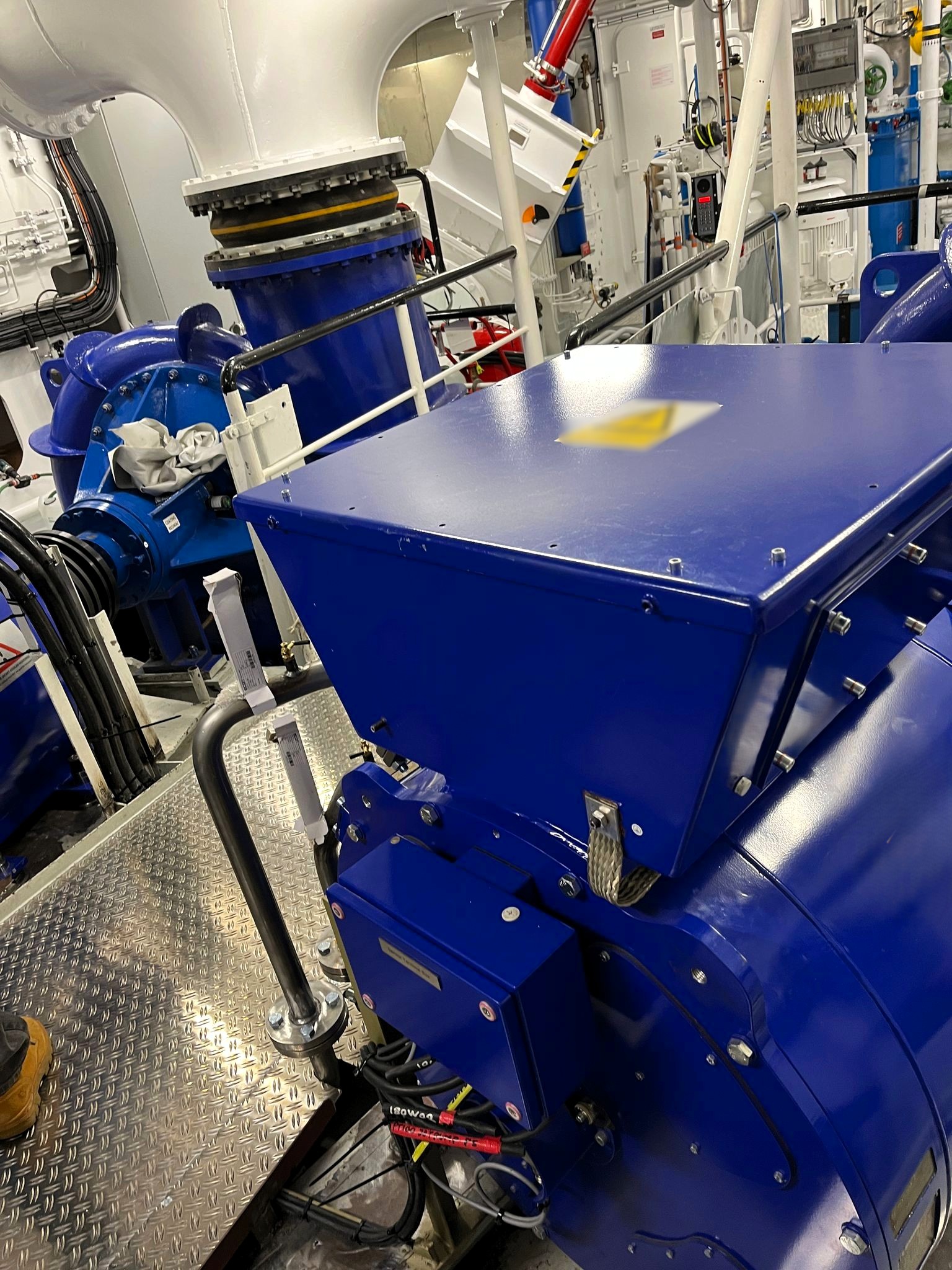

With these parameters, we got to work. We made a selection and sent out requests to various suppliers. Before long, we were sitting at the table with a manufacturer who understood exactly what we needed. We discussed everything in detail, and after thorough coordination, we designed an electric motor that met all the requirements. In close cooperation with the shipyard, we also worked out the mechanical side of things. This allowed the onboard modification to be carried out quickly and efficiently.

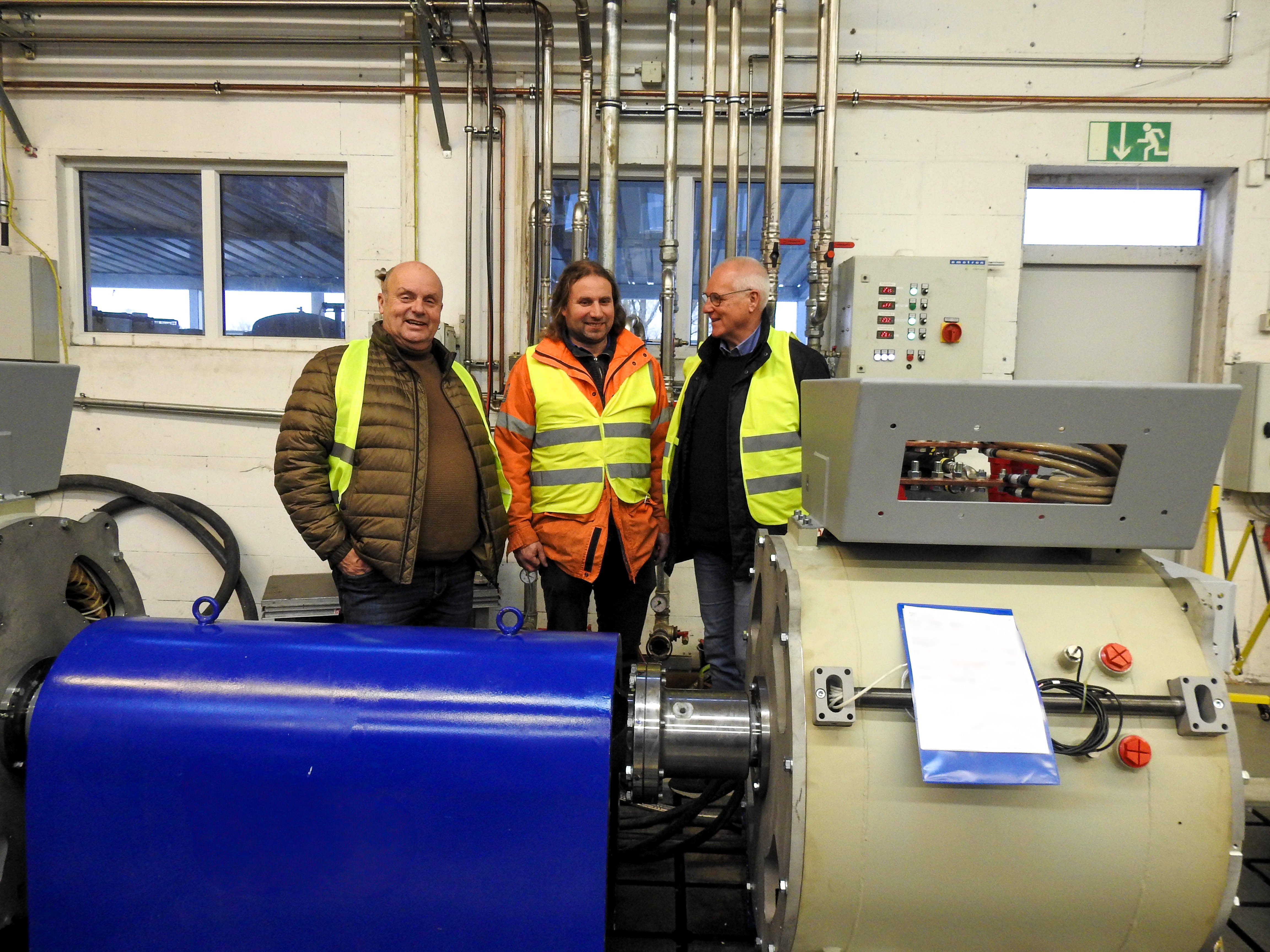

During the full-load test at the factory, we got a clear picture of the torque delivered by the motor. It turned out there was even some reserve capacity, exceeding everyone’s expectations.

The motors are now performing beyond the customer’s expectations, and the pumps are achieving their maximum output.

What’s more, energy consumption is lower than before – meaning less energy is used overall.

And last but not least: for the crew, it’s a breath of fresh air, as the motors produce significantly less noise. As a result, they sleep much more comfortably.

Thanks to the combined efforts and close cooperation with our clients @Aandrijftechniek Plus (@Ruud Hoogwerf) and @Van Oord (@Sven Koedoot), we achieved a result we can all look back on with proud smiles.